by This email address is being protected from spambots. You need JavaScript enabled to view it.

Every boat of a certain age has had some 'projects' done on her. Ours is no exception. The unfortunate part about these projects is that we mostly only get to do 'em once, so we seldom get 'em right on the first try. For some projects, if they're done suboptimally, we persist 'til they're right. For others, we just live with the result and resolve to be a little more thoughtful on the next project. On Magic, there are a handful of projects which have worked out tolerably well. If they help other Alberg 35 owners avoid some mistakes, it'll have been useful.

Magic in Boothbay

Magic in Boothbay

The kid on the housetop is optional equipment, self-deploying.

Cockpit - Looking Forward

- Winches. This makes single-handing much easier.

- The Loran, mounted on the bulkhead, to the right of the companionway.

- The inside binocular rack.

- The chart, which is usually kept on the housetop, under the dodger.

- A fresh beer, from the deck-loading icebox.

Other notable details:

The wheel is 24" dia. and should be 30".

Engine panel and controls are on the starboard seat riser.

The cockpit sole is 9/16" x 1 3/4" teak strips, set in 3M 9600 polysulfide caulk. It covers some very ugly structural repairs and stiffens the cockpit sole substantially.

The boom crutch fits into brackets on the bulkhead and passes through a 1" x 5" hole in the dodger. Anybody got any other ideas on how to have a dodger and a reasonably sturdy boom support? Until PHRF gives a rating credit for it, I'm not yet ready to consider a boom gallows.

Under the cushion at the forward end of the port seat, just abaft the bridgedeck, is the opening of the icebox. The ice goes in here. Beverages go on top. The helmsman can fetch himself a cold beverage without leaving his post.

Cockpit - Looking Aft

Winch bases are about 24" long and much sturdier than the originals.

Lazarette hatch has dovetailed mahogany frame, plywood core, and 1/8" teak veneer on top. Blackened epoxy between the teak veneer strips. Forward hatch cover (not in photos) has dovetailed mahog. frame and 3/8'' Lexan top.

Bow Roller - Outboard View and View from Above

The anchor roller is a Windline model URM-1. The mahogany block under it is about 2 1/4" thick. The roller has four 1/2" stainless bolts. The back pair go through the roller, the block the deck and a plywood backer. The forward pair run into epoxy plugs in the hull rail. The anchors I've used are a 35# Delta. and a 33# Bruce.. Both of these anchors occasionally hook the mooring pennant. This is a problem. I've relocated the starboard chock aft to try to correct this. This didn't do it. I may set the roller back 2-3". Mounted on the block abaft the roller are two Windline brackets. These are positioned to secure the anchor by the shackle hole.

Other details:

The Harken furler has been very trouble-free. The furler line is run through Sherman Johnson #40-501 fairleads outboard of the stanchion bases. Tidy.

Boom Reefing Blocks

Other details:

The topping lift has a snapshackle so that it can be disconnected to pass through a small (2") hole in the cockpit awning. I'm thinking that I should replace the topping lift with vinyl wire, dead-ended at the masthead, with a small tackle with a snapshackle at the bottom. Less windage and one less halyard to rap on the mast. A simple outhaul tackle (Harken blocks) is an improvement.

The Galley

On the whole, the stove's been OK, not nearly as bad as most of the blither re alcohol stoves. That said, I'm thinking of converting to Propane. If anyone's worked out a tidy propane tank installation, please share it.

Other notable details:

The handrail overhead is through-bolted to the outside handrails. They leak intermittently, but it's nice to have the security of something to grab. Nice for towels and charts, too.

The rack on the back bulkhead houses binoculars, some instruments, and a spice rack.

The replacement engine, a 20 hpWesterbeke is bulkier than the original Atomic Four. The box to house it can be seen. Footroom in the galley is a distant memory.

On the starboard side, where the icebox was, is now a quarterberth.

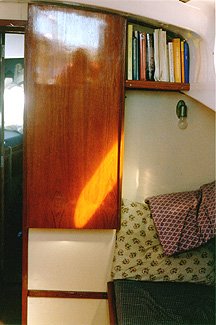

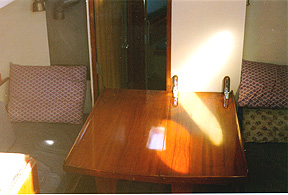

Cabin Table - Up and Down

The length of the leaves of the table is limited by the distance from the hinges to the overhead. The end is scribed to the overhead. The table is secured up by a small bronze hook visible just beneath the bookshelf on the right.

The rail on the bulkhead at berth height supports the flat which pulls out to make the starboard berth a (snug) double. The aft end of the flat has a leg.

On the port bulkhead is some ss sheathing for a charcoal burning cabin heater. It was not installed when the photo was taken. It's used often in Maine, seldom South of Cape Cod.